Blackwater Management in the Future

By May Wu

As cities continue to grow, more effective blackwater management is needed. Blackwater is wastewater that contains urine, flush-water, feces, and other excreta. Sewerage systems are a network of pumps and pipes to transfer wastewater and sewage. Currently, there are two traditional types of sewerage systems around the world: combined systems and separate systems. In a combined sewerage system, runoff water and sewage are both transferred through the same pipe.1 In a separated sewerage, these two wastewater types are transferred via different pipes.1 Theoretically, separated sewerage systems are more efficient than combined sewerage systems because the former can help to prevent combined sewerage overflows and can also handle large amount of stormwater more effectively.1 This article focuses on some solutions that may have immediate effects on improving blackwater management in sewerage systems. These solutions are divided into three categories and are written in more detail in the Solutions Explained section:

- Recovering Nutrients From Wastewater/Blackwater

One of the most common pollutants in blackwater or wastewater is phosphorus. The unnatural increase of nutrients such as phosphorus in a water body is known as eutrophication.2 Eutrophication boosts algae/plant growth and depletes the oxygen that are necessary for aquatic organisms in the water body.2 A water body covered with floating algae is usually a sign of excess phosphorus. The solutions proposed for this category are TetraPhos and Ostara Pearls technology. Both of these solutions seek to recover and recycle phosphorus from wastewater/blackwater.

- Blackwater Reuse

Nearly 663 million people around the world lack access to safe water and seventeen percent lack access to electricity.3 Therefore, turning wastewater/blackwater into potable water and electricity is an important step to increase people’s access to safe water and electricity. The solution we highlight in this article is the Janicki Omni Processor.

- The Future of Toilets

Current toilets use from 1.28 to 7 gallons of water per flush, that is an alarming 2336 to 12,775 gallons of water per person per year.4 However, nearly two and half billion people do not have access to a toilet. This section highlights some of the projects from the Bill and Melinda Gates Foundation’s Reinvent the Toilet Challenge: India 2012. The challenge requires competitors to design an inexpensive toilet/toilet systems that can operate “off the grid,” recover important nutrients such as phosphorous, filter out clean water, and convert biosolid into reusable energy.5

Solutions Explained

TetraPhos (CATEGORY I: Recovering Nutrients From Wastewater/Blackwater)

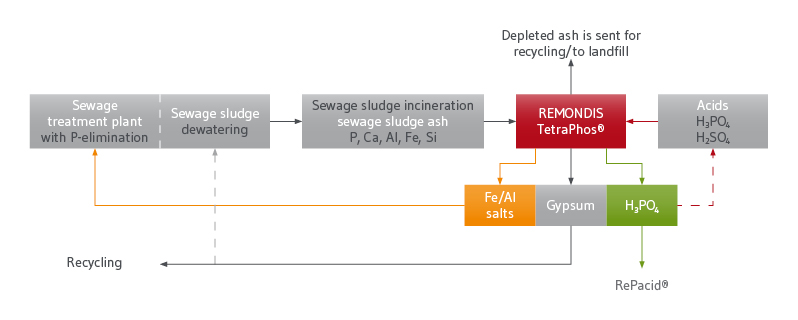

TetraPhos is a process developed by the Global Recycling company Remondis to recover phosphorus from wastewater.6 Phosphorus is an important raw material that can regulate plant protein synthesis and promote plant growth.7 With an 1.13 percent per year world population growth rate, more food is needed and hence more phosphorus is needed to grow plants.8 This also directly correlates to the future of urban agriculture. More information on urban agriculture solutions can be found here. Figure 1 below illustrates how the TetraPhos process works. In the TetraPhos process, sewage sludge is dissolved in phosphoric acid instead of the traditional hydrochloric acid.9 Using phosphoric acid creates three important materials: RePacid® phosphoric acid (fertilizer), gypsum, and iron/salt (precipitating agent in wastewater treatment). TheTetraPhos process can be combined with ReAlPhos®, which uses aluminum as a precipitating agent and recovers the phosphorous as calcium phosphate (more readily accessible).9

Figure 1. Detailed Process of the TetraPhos Process.9

Phosphorous Pearls (CATEGORY I: Recovering Nutrients From Wastewater/Blackwater)

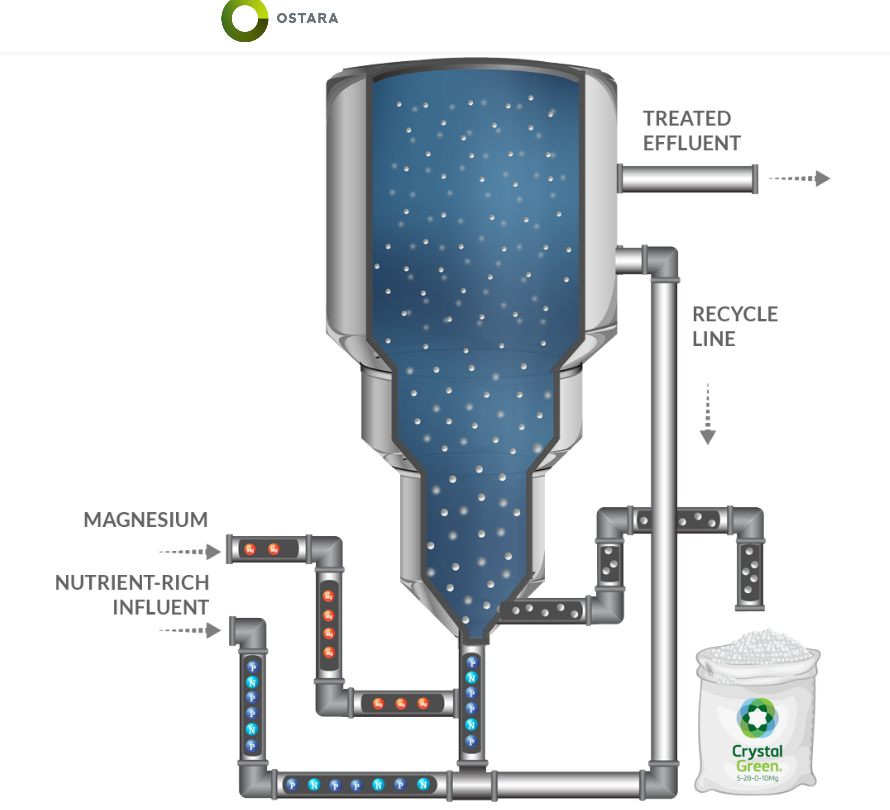

Ostara Pearls is another technology that focuses on recovering nutrients from wastewater and turning them into fertilizers. This Pearl technology revolves around the Pearl fluidized reactor. As shown in Figure 2, Ostara adds magnesium with a controlled pH to crystallize the nutrients into “highly pure fertilizer granules” of specific sizes.10 The 85 percent of phosphorus and the 10-30 percent of ammonia from the nutrients combined with magnesium form a precipitation of the granules.11 The granules are dried and bagged for immediate distribution once they reach the standard size for fertilizer blends.10 Ostara Pearls was recently awarded “Water’s Next Wastewater Award.”12 The Pearls not only meet environmental regulations and improve crop yield, but will also reduce the excess phosphorous in oceans. This is because plants absorb the Ostara Pearl fertilizer more than standard fertilizers, which helps to decrease polluted agricultural runoffs to oceans.11

Figure 2. The Basic Process for Ostara Pearls.10

Janicki Omni Processor (CATEGORY II: Blackwater Reuse)

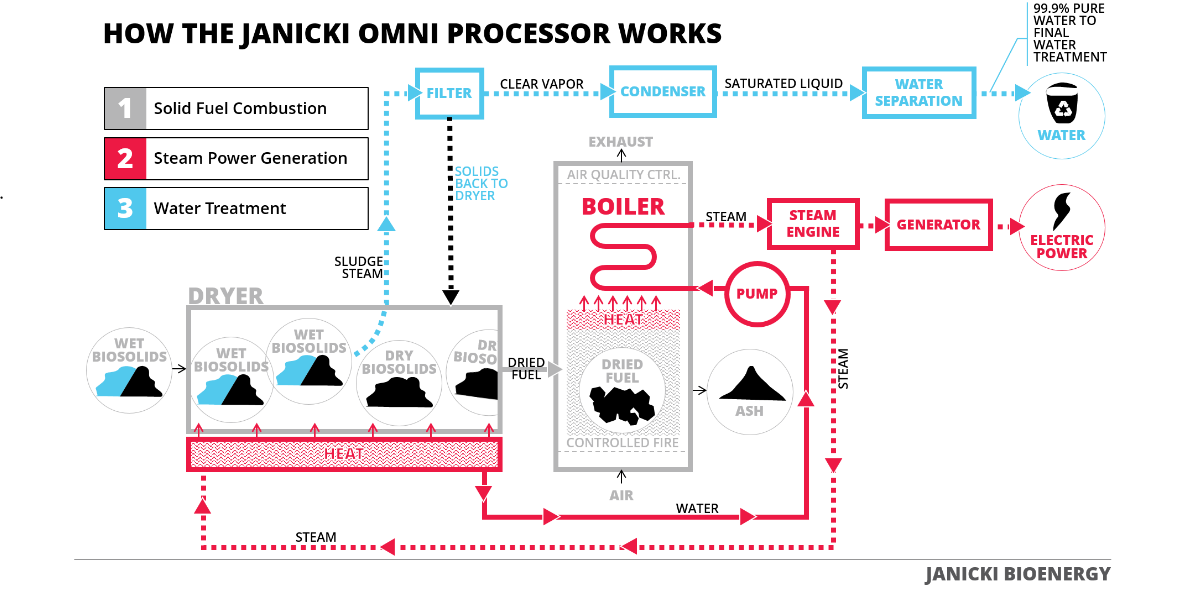

Janicki Bioenergy engineering firm in Seattle developed the Janicki Omni Processor to turn human feces into drinking water in a few minutes.13 In places that lacked modern sewage systems, truckers simply dump waste into rivers, which can damage the environment. The process (Figure 3) that the Omni Processor uses to turn sewage into drinking water can be broken down into three main processes: solid fuel combustion, steam power generation, and water treatment. In the solid fuel combustion process, wet biosolid is sent into a dryer to evaporate its moisture. Next, the dried biosolid is burned into a “dry fly ash” using a controlled fire.14 The ash and exhaust from the fire meets emission standards regulated by U.S. Clean Air Act before they are released into the environment. The controlled heat in the boiler heats up water to create a steam to be fed into the steam engine.14 The steam power generation process greatly improves the energy efficiency of the Omni Processor by making the entire system self sustaining. The steam engine in the system generates enough electricity to process incoming biosolids and the surplus electricity can be used for other purposes.14 Waste heat from the steam engine is transferred back into the dryer as heat and is used to process the next batch of wet biosolid.14 The water treatment process completes the Omni Processor. The extra moisture and steam generated in the dryer is sent through a series of water filters and become drinkable potable water.14 The Omni Processor emits no smell.14 Each processor costs 1.5 million dollars and can processes biosolids from up to “100,000 people, produces up to 86,000 liters of potable water a day, and a net 250 kilowatts of electricity.”13

Figure 3. The Omni Processor Breakdown.14

Here is a video of Bill Gates trying out water processed from the Omni Processor.

| Video 1. Bill Gates drinking water processed by the Janicki Omni Processor. Source: YouTube. |

Bill and Melinda Gates Foundation Reinvent the Toilet Challenge (CATEGORY III: The Future of Toilets)

These are some of the designs presented at the Reinvent the Toilet Challenge and possible options for future toilets. The full list of all the designs can be found here.

Hydrocyclone Toilet

Designed by Asian Institute of Technology from Thailand, the Hydrocyclone toilet can separate the liquid and solid waste from flush water immediately after flushing. The solids are immediately heated and disinfected using electrochemical technology. The liquid waste is cleaned and filtered for agricultural waste.

Caltech Toilet

The Caltech Group won the Bill and Melinda Gates Foundation’s Reinvented Toilet Challenge in 2012 by developing a solar-powered toilet that “integrates an electrochemical reactor to treat wastewater.”15 The design implements inexpensive sensors to detect leaks and sends alerts through an app whenever there are leaks or other problems in the toilet system.16 The toilets are currently used in Mahatma Gandhi University in Kerala, a public space in Ahmedabad, and in China.16

Nanomembrane Toilet (Cranfield University)

The toilet design uses hollow -fiber dense polymer nano-membranes to remove water from feces. The left over solid is covered with a nanospray to contain pathogens and odor. The whole system is powered by a hand crank or bicycle crank.

Conclusion

Blackwater management becomes more important as cities and the world population expand. To improve blackwater management, we propose solutions in categories such as: recovering nutrients from blackwater reuse and future toilets. TetraPhos, Ostara Pearls, Janicki Omni Processor, hydrocyclone toilet, Caltech Toilet, and the Nanomembrane Toilet are exemplary solutions that seek to improve blackwater management.